Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

The honeycomb panel production line equipment is a complex system engineering that requires coordination and cooperation between various parts to ensure product quality and production efficiency. With the development of technology and the progress of industry, the equipment of honeycomb panel production line is constantly updated and improved to meet market demand and improve production efficiency.

Among the honeycomb panel production line equipment, the aluminum-plastic composite panel production line is one of the most important equipment. Aluminum plastic composite panel is one of the main materials of honeycomb panel, which is made by high-temperature composite of one layer of aluminum alloy panel and one layer of plastic panel, and has excellent weather resistance and corrosion resistance. The cutting machine is used to cut aluminum-plastic composite panels into different sizes for subsequent processing.

Provide some precautions for purchasing equipment for Dalian honeycomb panel production line

1. Clarify one's own needs:

Production product type: Determine the material (such as aluminum honeycomb board, plastic honeycomb board, paper honeycomb board, etc.), specifications (thickness, size, etc.), and purpose of the honeycomb board to be produced. There are significant differences in equipment for honeycomb panel production lines made of different materials. For example, aluminum honeycomb panel production lines require stretching machines, composite presses, and other equipment, while plastic honeycomb panel production lines require extruders, composite devices, and so on. Select appropriate equipment according to the specific requirements of the production product to avoid mismatch between equipment functions and production needs.

Production scale: Select production line equipment with appropriate capacity based on expected production output and market demand. If the production scale is large, equipment with high automation and production efficiency should be selected; If it is small-scale production or just starting to enter the field of honeycomb panel production, you can first choose some small or economical equipment, and then gradually upgrade according to business development.

2. Equipment quality and performance:

Material and Manufacturing Process: Check the material quality and manufacturing process of the equipment, such as whether the body structure is sturdy, whether the welding parts are firm, and whether the machining accuracy of the components is high. For example, for some key components such as the screw of the extruder and the pressure plate of the composite press, the wear resistance and corrosion resistance of their materials directly affect the service life and production quality of the equipment.

Operational stability: The equipment should remain stable during operation to avoid frequent malfunctions or shutdowns. The stability of the device can be evaluated by reviewing its operational test reports and understanding its usage in other manufacturers.

Production efficiency and accuracy: Production efficiency is an important indicator for measuring equipment performance, and equipment with high production efficiency should be selected according to production needs. At the same time, the production accuracy of the equipment is also very important, such as the uniformity of the glue coating equipment and the cutting accuracy of the cutting equipment, which will directly affect the quality of the honeycomb board.

3. Supplier selection:

Supplier qualifications and reputation: Choosing a supplier with good qualifications and reputation can be judged by reviewing the supplier's business license, production license, quality certification and other certificates, as well as understanding the supplier's reputation and customer evaluations in the industry.

After sales service: High quality after-sales service is the guarantee for the normal operation of equipment, and suppliers who can provide timely and professional after-sales service should be selected. Understand the supplier's after-sales service system, including the technical level, response speed, and maintenance cycle of after-sales personnel.

Technical support: It is also very important for suppliers to provide technical support such as equipment installation and debugging, operation training, and technical consultation. Before purchasing equipment, it is necessary to clarify the content and methods of technical support with the supplier.

4. Cost budget:

Equipment price: When purchasing honeycomb panel production line equipment, do not only focus on the price of the equipment, but also consider factors such as equipment quality, performance, and after-sales service comprehensively. Avoid purchasing equipment with excessively low prices to ensure that the quality and performance of the equipment do not meet production needs; At the same time, do not blindly pursue high-end equipment, which may lead to high investment costs.

Operating costs: In addition to the purchase price of the equipment, it is also necessary to consider the operating costs of the equipment, such as energy consumption, raw material consumption, equipment maintenance costs, etc. Choosing equipment with low operating costs can reduce production costs and improve the economic efficiency of the enterprise.

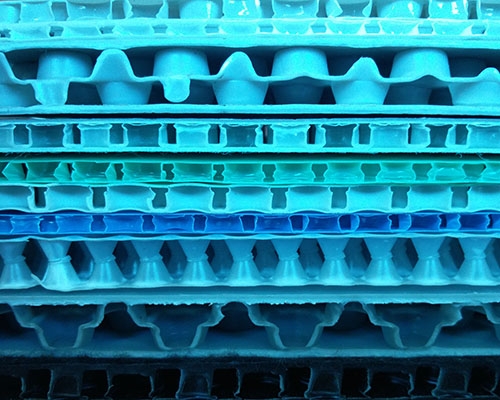

The honeycomb panel production line is a very important production equipment in modern industry, mainly used to produce various specifications of honeycomb panel products. Honeycomb panel is a lightweight structural board composed of multiple layers of sandwich paper or other materials. Due to its unique structure, it has excellent strength and thermal insulation performance, and is widely used in fields such as building decoration, automobile manufacturing, aerospace, etc.

Honeycomb panel production line equipment usually includes the following main parts: aluminum-plastic composite panel production line, cutting machine, aluminum foil machine, embossing machine, hot air stove, cooling machine, automatic feeding machine, mixer, melting machine, etc. These devices each undertake different functions, work together, and ultimately produce high-quality honeycomb panel products.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com