Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

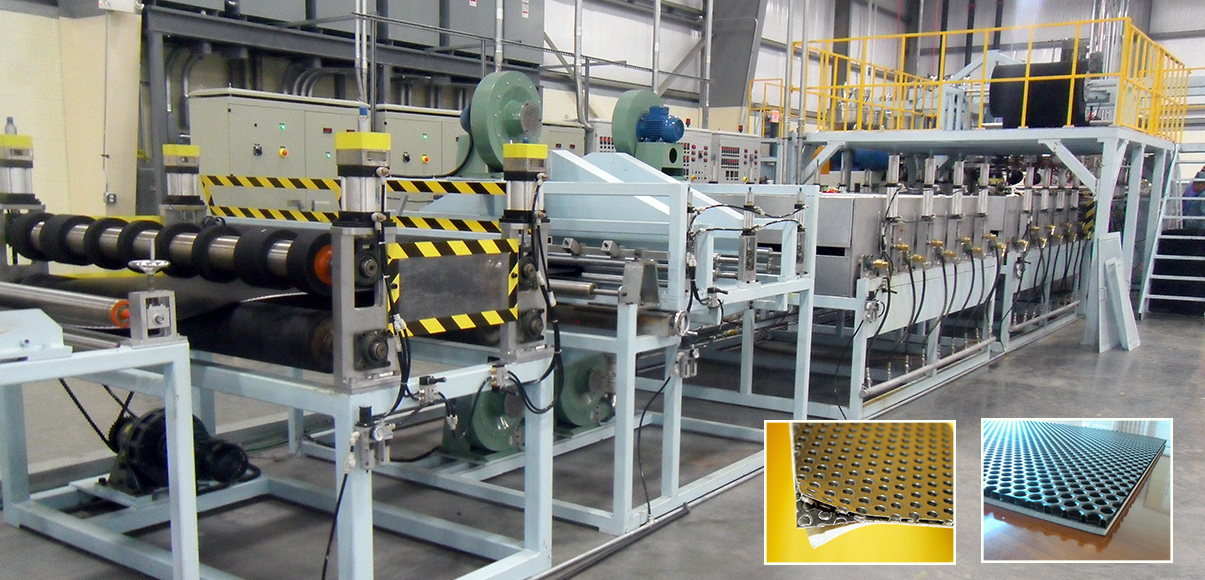

Honeycomb panel production line equipment is a very important production equipment that plays a crucial role in the production process of honeycomb panels. It can improve production efficiency, reduce costs, and improve product quality, which is of great significance for promoting the production and development of honeycomb panel products. In the future, with the increasing demand for honeycomb panel products, honeycomb panel production line equipment will be more widely used and developed.

The working principle of the honeycomb panel production line equipment is mainly to produce finished honeycomb panels from raw materials through a series of collaborative devices. Among them, each part of the equipment has its specific function and role, and the production of honeycomb panels is achieved through a continuous process flow. The entire production line equipment operates stably, with high production efficiency, and can meet market demand.

What are the usage methods and precautions for the equipment on the Dalian honeycomb panel production line?

usage method:

Preparation work: Before using the honeycomb panel production line, it is necessary to inspect and clean the equipment to ensure that it is in good working condition. At the same time, it is necessary to prepare the raw materials and accessories required for production.

Parameter setting: Set the relevant parameters of the equipment, such as temperature, speed, pressure, etc., based on the type and specifications of the honeycomb panel to be produced. Ensure that the parameter settings are correct to ensure the production of honeycomb panels that meet the requirements.

Power on inspection: After starting the device, conduct a running test to check if the device is operating normally and if there are any abnormal noises or odors. After ensuring the normal operation of the equipment, formal production begins.

Processing and production: Follow the operating steps in the equipment manual to gradually process and produce honeycomb panels. Pay attention to monitoring the operation status of the equipment, promptly identify and handle problems.

Quality inspection: After production is completed, the honeycomb panels produced are subjected to quality inspection to ensure compliance with relevant standards and requirements. If quality problems are found, adjust the equipment parameters in a timely manner for re production.

matters needing attention:

Safety first: When operating the honeycomb panel production line, pay attention to the safe use of the equipment. Do not touch the equipment and transmission components randomly during operation to avoid accidents.

Pay attention to cleaning: Regularly clean and maintain the equipment to maintain its good condition and service life. Especially the cleaning and lubrication of internal components of the equipment are crucial for its normal operation.

Pay attention to maintenance: Regularly carry out equipment maintenance work, such as replacing vulnerable parts and lubricating components, checking circuits and transmission systems, etc. Ensure long-term stable operation of the equipment.

Operating standards: When operating the honeycomb panel production line, follow the operating steps in the equipment manual to avoid equipment failure or accidents caused by incorrect operation.

Quality control: When producing honeycomb panels, strict quality control is necessary to ensure that the products produced meet relevant standards and requirements. Timely identify and address quality issues that arise during production.

The workflow of honeycomb panel production line equipment usually includes the following steps: first, raw material processing, mixing, heating, dehumidification and other related raw materials before sending them into the extruder; Next is extrusion molding, where the raw materials are extruded into shape through a high-temperature and high-pressure extruder; Then there is cooling and shaping, where the extruded honeycomb board is cooled by a certain cooling device to solidify and form; Then cutting and packaging, cutting and packaging the cooled and solidified honeycomb board, and the production of the finished honeycomb board is completed.

The honeycomb panel production line equipment mainly consists of the following parts: raw material processing system, forming system, curing system, and cutting system. The raw material processing system mainly includes cutting and processing equipment for raw materials, which is used for preliminary processing of raw materials. The forming system is to shape processed raw materials into honeycomb shaped boards through molds, while the curing system is to heat and solidify the formed boards to meet the requirements of strength and stability. The cutting system is used to cut the cured board into honeycomb board products that meet the requirements.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com