Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

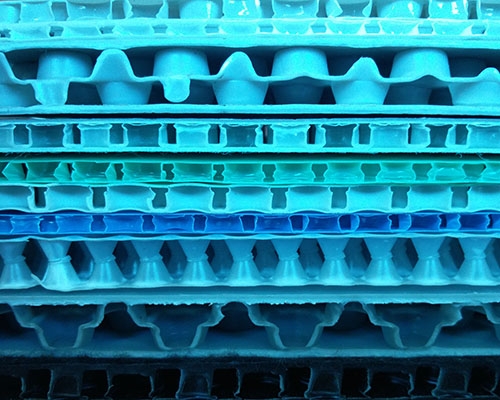

The honeycomb panel production line equipment is a set of equipment systems used for producing honeycomb panels, including coil uncoilers, coating machines, drying and drying channels, molding machines, cutting machines, and stacking machines. Through a series of process steps, raw materials are processed and manufactured into honeycomb panel products. Auxiliary equipment such as waste recycling systems, waste gas treatment systems, and automation control systems can improve production efficiency and product quality. Honeycomb panel production line equipment plays an important role in fields such as construction, transportation, electronic communication, and new energy.

The drying equipment in the production line equipment is a crucial part of the honeycomb panel production process. Wet bonded panels need to undergo drying treatment to remove moisture during the bonding process, so that the panels have stable dimensions and properties. Drying equipment usually adopts a hot air circulation system, which gradually reduces humidity by heating and circulating air to achieve drying of the board. The honeycomb panel production line equipment also includes cutting equipment, which is used to cut the formed sheet into dimensions that meet the requirements for subsequent processing and use.

What are the specifications and size range of honeycomb panel production line equipment?

The honeycomb panel production line equipment usually includes the following main equipment:

Cutting machine: used to cut raw materials (such as metal or plastic) into the required specifications and dimensions. The cutting machine can be adjusted as needed to meet the size and shape requirements of different honeycomb panels.

Punching machine: used for punching holes on honeycomb boards. These holes can be used to fix other parts or accessories to the honeycomb panel, and can also be used to enhance the strength of the honeycomb panel. Punching machines typically have molds of different sizes and shapes to adapt to different aperture and layout requirements.

Welding equipment: used to weld various components of honeycomb panels. Welding equipment can be manually operated or automatically operated. Welding equipment is usually adjusted based on the size and shape of the honeycomb panel.

Pressing machine: used to press the various components of the honeycomb board to ensure they are tightly connected together. Pressing machines typically have molds of different sizes and shapes to accommodate honeycomb panels of different specifications and sizes.

Coating equipment: used to apply protective coatings on honeycomb panels. This coating can prevent honeycomb panels from corrosion or other forms of damage. Coating equipment typically has the function of adjusting coating thickness and uniformity.

The size range of honeycomb panel production lines varies according to different applications, and the following are some common size ranges:

Thickness: The thickness range of honeycomb panels typically ranges from a few millimeters to a few centimeters. For honeycomb panels with special requirements, the thickness may be larger.

Width and length: The width and length of honeycomb panels can be adjusted according to specific needs. In general, the width and length range from a few millimeters to a few meters.

Aperture: The aperture on the honeycomb board can be adjusted as needed. Usually, the range of aperture ranges from a few millimeters to a few centimeters.

Honeycomb board production line equipment typically consists of multiple processes, including material processing, honeycomb structure manufacturing, bonding treatment, drying, and cutting. Raw materials such as aluminum and steel need to be treated to remove surface oxides and pollutants, making their surfaces clean. Then, through a series of processing techniques, the raw materials are processed into honeycomb structured panels. This process usually involves stamping, gluing, embossing, and other processes, which require the use of specialized equipment to complete. Gluing is an important step in the manufacturing of honeycomb panels. By gluing two or more honeycomb panels together, the thickness and strength of the panels can be increased. The bonding process requires the use of adhesives and pressure equipment to ensure the quality and bonding strength of honeycomb panels.

The cardboard/plastic sheet production machine is the core equipment of the honeycomb panel production line, used to manufacture the basic materials for honeycomb panels. The cardboard production machine mainly consists of a pulp processing unit, a forming unit, and a drying unit. It processes the pulp into cardboard and shapes it into sheets with a honeycomb structure. A coating machine is used to apply special coatings to cardboard or plastic sheets to enhance their flame retardancy, water resistance, and durability. The coating machine can perform multiple coatings as needed to achieve the required performance requirements.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com