Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

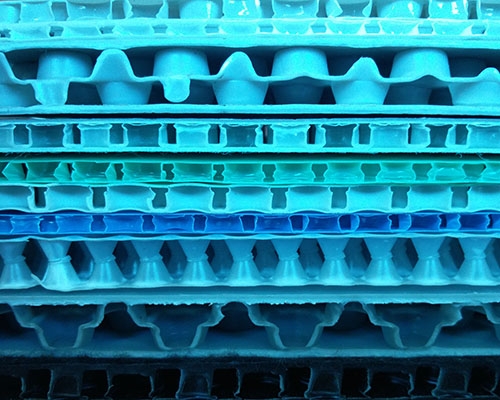

The honeycomb panel production line equipment is a key tool for achieving large-scale production of honeycomb panels, and its design and operation are crucial for the development of the honeycomb panel industry. Through continuous research and innovation, honeycomb panel production line equipment can further improve production efficiency, product quality, and market competitiveness, better meeting the needs of different industries for honeycomb panel products.

Hot pressing equipment for honeycomb panels. These devices typically include hot presses, heating systems, and cooling systems. In the manufacturing process of honeycomb panels, the core and skin materials need to be combined through hot pressing. The hot press provides high temperature through a heating system, which combines the core material and skin material under a certain pressure. The cooling system is used for rapid cooling to ensure the strength and stability of the honeycomb panel.

What should be paid attention to during the maintenance of honeycomb panel production line equipment?

Equipment maintenance requires attention to safety. During the maintenance process, it is necessary to wear appropriate personal protective equipment, such as gloves, goggles, and protective masks, to ensure the safety of personnel. In addition, before maintenance operations, it is necessary to cut off the power supply of the equipment, ensure that the equipment stops running, and correctly lock the power contactor with the key. Maintenance can only be carried out after confirming the safety of the equipment.

Secondly, equipment maintenance requires a certain level of technical and professional knowledge. Maintenance personnel need to understand the structure and working principle of honeycomb panel production line equipment, and master relevant maintenance skills. For common fault problems, maintenance personnel should be able to accurately determine the cause of the fault and quickly take the correct repair measures.

Regular maintenance and upkeep: Regular maintenance and upkeep of equipment is an important measure to extend its lifespan. Regularly inspect the lubrication system, electrical system, and transmission system of the equipment to maintain their normal working condition. Regularly clean the equipment to prevent dust and foreign objects from entering the interior.

Selection of repair materials: The materials used during the repair process need to be selected with suitable materials and specifications. For example, the lubricating oil used must meet the requirements of the equipment to avoid equipment failure due to insufficient lubrication. At the same time, the quality of repair materials should also be guaranteed to ensure their performance and reliability.

The raw material processing system is the first step of the honeycomb panel production line, mainly used for processing raw materials. Commonly used raw materials include paper, pulp, cellulose, honeycomb core paper, etc. Raw material processing systems typically include equipment such as paper cutting machines, pulp mixers, and raw material crushers, which are used to cut, mix, and crush raw materials for subsequent molding processing.

Honeycomb panel production line equipment plays an important role in the construction and other industries. They can be used to manufacture various types of honeycomb panels, such as aluminum alloy honeycomb panels, plastic honeycomb panels, and paper honeycomb panels. Honeycomb panels are widely used in building decoration, automotive manufacturing, packaging materials, and other fields, and are highly favored due to their lightweight, high strength, and good insulation performance.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com