Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

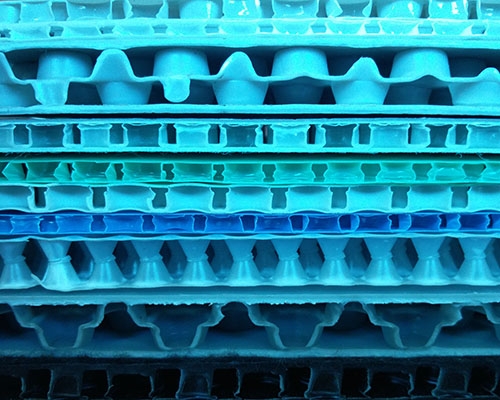

The honeycomb panel production line equipment includes raw material preparation equipment, coating machine, oven, trimming and processing equipment, quality inspection equipment, and packaging equipment. The use of these equipment and the reasonable arrangement of supporting processes can ensure the production efficiency and stable quality of honeycomb panels. With the continuous progress of technology, the honeycomb panel production line equipment is also constantly being updated to meet market demand and improve production efficiency.

Modern honeycomb panel production line equipment includes various types of equipment, each with its specific functions and purposes. The first step of the honeycomb panel production line equipment is the preparation of raw materials. This includes cutting wood or other fibrous materials into appropriate sized blocks for subsequent processing. Cutting equipment uses high-speed rotating cutting tools to cut raw materials into the required dimensions.

Is the honeycomb panel production line equipment suitable for various materials?

The applicability of honeycomb panel production line equipment is related to the characteristics of the materials to be processed. Generally speaking, honeycomb panel production line equipment is suitable for various materials, including metal, plastic, cardboard, etc.

For metal materials, honeycomb panel production line equipment can use various metal plates, such as aluminum plates, stainless steel plates, etc. Metal sheets can be processed through honeycomb panel production line equipment such as cutting, punching, and bending to form honeycomb structures, which are then subjected to surface treatments such as chrome plating, spraying, etc. to produce honeycomb panels.

For plastic materials, honeycomb panel production line equipment can use various plastic sheets, such as polypropylene, polyvinyl chloride, etc. Plastic sheets can be hot-pressed or glued through honeycomb production line equipment to form honeycomb structures, and then surface treated, such as spraying, printing, etc., to make honeycomb sheets.

For cardboard materials, honeycomb board production line equipment can use various cardboard materials, such as kraft cardboard, cardboard, etc. Cardboard materials can be cut and folded through honeycomb production line equipment to form honeycomb structures, and then subjected to surface treatments such as gluing and hot pressing to produce honeycomb panels.

Honeycomb board is a lightweight and sturdy structural material composed of multiple layers of thin plates, commonly used in the construction and manufacturing industries. It is composed of a honeycomb like core layer between two layers of panels, which gives the honeycomb panel excellent mechanical and thermal insulation properties. In order to produce high-quality honeycomb panels, a complete production line is required, including various equipment and processes.

The equipment that enters the next stage after pre-treatment of raw materials is the fiber separation equipment. These devices are used to separate the fiber layers in the raw materials for subsequent processing. Fiber separation equipment is usually composed of a series of serrated blades and rotating screens. The blade cuts the raw material into fiber layers, and then separates the fiber layer from other impurities through a sieve. This process is called degreasing.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com