Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

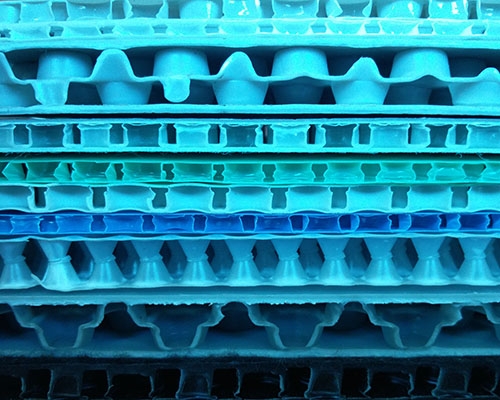

Honeycomb panels are divided into cushioning honeycomb panels and packaging honeycomb panels according to their functions. Due to its unique structure, it can improve compressive strength, while paper honeycomb panels can more effectively reduce costs. Honeycomb panels generally have apertures of 8mm, 16mm, and 32mm, and paper honeycomb panels weigh 280g/1 square meter. Paper honeycomb boards can be used to make various types of pallets, liners, packaging boards, packaging boxes, etc.

The aluminum honeycomb panel uses A-grade and B-grade fire-resistant aluminum alloy as the raw material, which can withstand high temperatures of over 600 degrees Celsius, has low density, and is lightweight. The advantages of advanced technology and scientific construction are outstanding in terms of scale, flatness, pattern color, and can be processed according to requirements in terms of shape, surface treatment, installation system, etc. In addition, the surface layer can be made of aluminum alloy or other materials according to customer needs. Common materials in daily life include copper, zinc, stainless steel, marble, etc.

The purpose of honeycomb panels produced by honeycomb panel production line equipment

(1) Building curtain wall exterior wall hanging plate

(2) Interior decoration engineering

(3) Billboard

(4) Shipbuilding

(5) Aviation manufacturing industry

(6) Indoor partitions and product display stands

(7) Commercial transport vehicles and container vehicle bodies

(8) Bus, train, subway, and rail transit vehicles

(9) For the modern furniture industry with strict environmental requirements, using aluminum honeycomb panels as the processing material for furniture is a good material choice in the new century. Its completely non-toxic green quality allows furniture manufacturers to process furniture without unnecessary environmental procedures.

Honeycomb sound-absorbing boards can be designed to produce finished products with different perforation rates to meet the required sound-absorbing requirements. They can also be manufactured into various curved surfaces and shapes according to the designed appearance. Due to its sufficient rigidity, honeycomb panels are subjected to relatively small vibration in the sound field, which is only about one-sixth of that of single panels. Therefore, they can greatly reduce noise interference caused by resonance.

Honeycomb cores solve the pain points of traditional materials, not only being lightweight, but also exhibiting its excellent characteristics. Unlike wooden boards, which are prone to moisture, poor sound insulation, and high weight, the honeycomb shaped cavity composed of honeycomb cores also has the characteristics of sound insulation and noise reduction. It is a pollution-free, recyclable, and environmentally friendly material. Secondly, the honeycomb core plays a crucial role in ensuring the high flatness of stainless steel honeycomb panels.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com