Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Aluminum honeycomb panel: Compared to stainless steel honeycomb panel, the strength of the panel is worse. At the same time, after long-term exposure to sunlight, rain, or industrial waste gas pollution, the surface oil, dirt, and naturally formed loose oxide layer can seriously affect the surface decoration effect of aluminum honeycomb panel, and its durability is slightly poor. But its board colors, textures, and patterns are more diverse and diverse.

The surface coating of aluminum honeycomb panels is fluorocarbon baking paint, polyester powder spraying, acrylic baking paint, fluorocarbon or polyester roller coating decoration. Due to the fact that aluminum honeycomb panels are equivalent to countless I-beam structures, they are endowed with greater rigid bending strength and smaller bending deformation. The honeycomb panel has a high flatness, which is much better than single aluminum panel and aluminum plastic panel. It can manufacture larger size panels (1.5m × 10m), meeting the designer's design concept. In addition, due to the ability of aluminum honeycomb panels to process shapes such as "L", "U", and single curved arcs, they can meet the requirements for irregular shapes in architectural decoration.

How to select honeycomb panels for production line equipment

1. Thickness of honeycomb panel

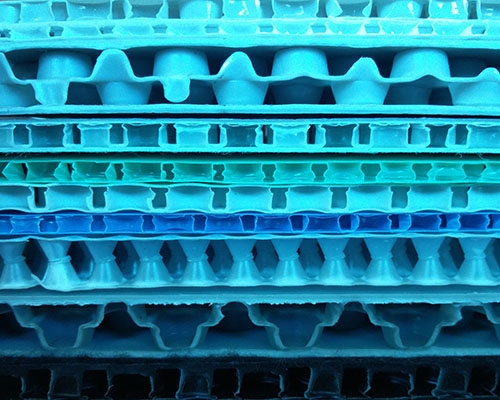

The thickness of honeycomb panels generally ranges from 3 millimeters to 7 millimeters, which mainly depends on the weight of the product that the customer needs to transport. The larger the product weight, the thicker the honeycomb panel needs to be selected. Try to choose the appropriate thickness while meeting the needs, not just pursuing thickness.

2. Color of honeycomb panels

Most honeycomb panel manufacturers have blue and black inventory colors, although some manufacturers also have other colors. However, regular colors are usually cheaper due to inventory. Black can also be subdivided into three characteristics: general, anti-static, and conductive. If it is not a company in the electronics industry, choose general.

3. The price of honeycomb panels

Don't just pursue low prices, get what you pay for. Low priced honeycomb panels often have poor quality and are not durable, requiring frequent purchases, which cannot save money. Therefore, when choosing honeycomb panels, try to choose relatively cheap honeycomb panels from large manufacturers.

During installation, the fasteners are directly connected to the aluminum honeycomb veneer and fastened to the crossbeam. Firstly, place the single aluminum honeycomb decorative panel in the designated position, then clip the honeycomb aluminum panel into the beam, and then fine tune the seam of the panel. The edge of the aluminum honeycomb decorative panel is fixed to the crossbeam with galvanized screws. When the irregular plate is not firmly fixed after installation, galvanized screws can be used to fix the edge of the aluminum honeycomb decorative plate on the beam to strengthen the connection. After the installation of the aluminum honeycomb panel, the height can be adjusted through the screws at the top (each aluminum honeycomb panel has adjustable fasteners at the top).

Honeycomb aluminum honeycomb panel is a metal composite panel product developed by combining industrial composite honeycomb panel technology. The honeycomb aluminum plate adopts a "polygonal honeycomb sandwich" structure, with a surface that can be roller coated or coated with film. It is a highly weather resistant decorative layer, combined with high-strength aluminum alloy plate, as the surface layer and bottom plate. The middle polygonal aluminum honeycomb core is a metal composite plate formed by high-temperature and high-pressure composite pressing.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com