Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

The aluminum honeycomb panels produced by the honeycomb panel production line equipment are mainly suitable for hanging panels on the exterior walls of large building curtain walls, indoor decoration projects, such as the interior and exterior walls, roofs, awnings, billboards, etc. of airports, railway stations, subway stations, and large sports venues; High speed rail and ship rail transit, aviation manufacturing, indoor partitions and commodity display platforms, commercial transport and container vehicle bodies, modern furniture industry, etc.

Honeycomb material is a lightweight material with low material consumption and low energy consumption. It can not only save a lot of natural resources such as wood, but also greatly reduce the use of white foam that pollutes the environment. Due to the special honeycomb structure of honeycomb paper cores, which can save a lot of materials and improve the characteristics of the board, honeycomb composite boards have long been used in high-tech fields such as aviation and aerospace, such as the fairing of launch vehicles, structural components of aviation and space shuttles, etc. Honeycomb structural materials are generally made of recycled paper, so in other fields, they can be made into various lightweight panels to replace solid wood panels, or into lightweight wall panels and partitions for building materials and decorative panels.

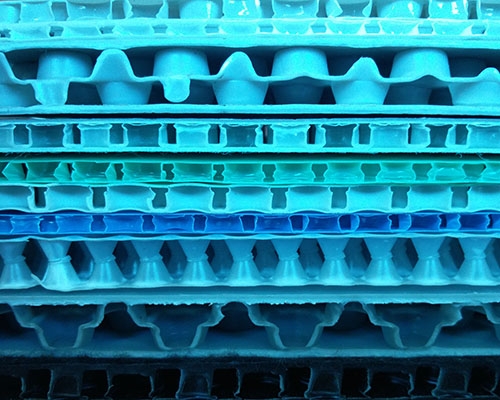

What are the characteristics of PP honeycomb panels produced by honeycomb panel production line equipment

Waterproof and moisture-proof, with a honeycomb structure, it is lightweight and has advantages such as shock resistance, insulation, and sound insulation. The design concept of PP honeycomb panel structure comes from the I-beam structure: the surface plate is equivalent to the wing plate of the I-beam, mainly bearing normal stress; The middle honeycomb layer is equivalent to the web of an I-beam and mainly bears shear stress. The structural strength of the two surface plates is high, with a large cross-sectional moment of inertia, resulting in good stiffness and high bending strength; The intermediate sandwich layer is modeled after a honeycomb structure, using fewer materials but with high shear strength and good stability; The optimized combination of the surface plate and honeycomb intermediate layer makes PP honeycomb board have the advantages of light weight, high strength, and good stiffness. The appropriate selection of surface panels and honeycomb panels can also achieve good seismic, thermal, sound insulation, and other performance, and can be made into fire-resistant PP honeycomb panels. Due to the above advantages, PP honeycomb panels were first used in the aviation and aerospace sectors, and then widely used in architectural fields such as decoration, curtain walls, roofs, floors, and other industrial sectors such as automobiles, trains, ships, light rail, subways, elevators, etc.

The structure of honeycomb paperboard is usually made by bonding surface paper, inner paper, and honeycomb core paper. The core hole of honeycomb cardboard is a closed structure, filled with air and not circulating with each other, thus providing good sound insulation and thermal insulation performance. After special treatment, honeycomb cardboard can also be flame retardant, moisture-proof, waterproof, and shockproof. Honeycomb cardboard boxes can be used for outer packaging of heavy products such as mechanical products and components, electronics, electrical products, motorcycles, etc. It can also be used for packaging fragile and pressure resistant products such as glass and ceramics.

The main part of PP honeycomb board is the honeycomb structure. The honeycomb structure design source of the beam structure: the dashboard represents I-beam steel, mainly supporting normal stress; The intermediate cell layer corresponds to the keel network and mainly supports shear stress. The two instrument panels have greater structural strength and greater rotational inertia of the cross-section, resulting in better stiffness and bending strength; Intermediate biomimetic simulation of natural honeycomb sandwich structures and materials, but with good shear strength and stability; The optimization of the middle layer of the sprint board and the cell composition make the honeycomb board lightweight, high strength, stiffness, and good character. Choosing appropriate instrument panels and honeycomb panels can achieve good seismic, thermal, and sound insulation performance when they are made into fireproof honeycomb panels, thermal insulation, and sound insulation.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com