Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

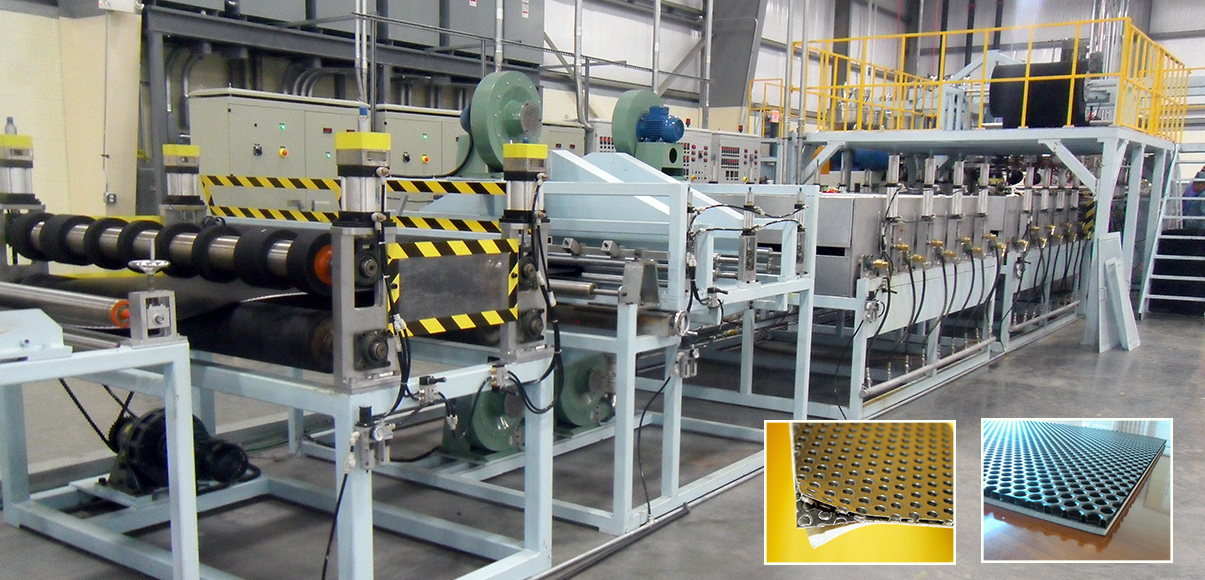

The press is the core part of the honeycomb panel production line equipment, which is used to press the raw materials that have been coated and preheated into the shape of honeycomb panels. Presses usually use hydraulic or pneumatic systems, which can accurately control pressure and temperature to ensure stable quality of honeycomb panels. Glue coating machine is a device used to apply glue on the surface of raw materials. Its function is to increase the adhesion of raw materials, improve the strength and stability of honeycomb panels. Glue coating machines usually use rollers or nozzles for coating, and the uniformity of coating has a significant impact on the quality of honeycomb panels.

The formation of honeycomb panels requires a bonding process to bond the various layers of raw materials together to form a cohesive structure. The bonding equipment includes a glue sink, a laminating machine, etc., used to bond the raw materials of each layer. Heating equipment is commonly used to bake honeycomb panels to achieve the desired strength and hardness. Heating equipment includes ovens, drying equipment, etc., which use heating treatment to achieve ideal performance indicators for honeycomb panels.

What factors should be considered when selecting equipment for a honeycomb panel production line?

Production scale: Production scale is an important factor in selecting equipment. If the production scale is small, small equipment can be chosen to meet the demand; If the production scale is large, it is necessary to consider choosing large equipment to improve production efficiency.

Technical requirements: Different production line equipment has different technical requirements, and suitable equipment should be selected according to production needs. For example, it is necessary to consider the technical requirements of equipment automation level, production speed, stability, and other aspects.

Production materials: Select production line equipment suitable for materials according to production needs. Different materials require different equipment for processing, and it is necessary to consider whether the equipment can meet production requirements.

Cost considerations: When choosing production line equipment, factors such as equipment price, operating costs, and maintenance costs need to be considered. Choose suitable equipment based on the budget to avoid overspending.

Quality requirements: Select equipment according to product quality requirements. If the product has special requirements, it is necessary to select equipment that can meet the requirements to ensure product quality.

Production efficiency: Consider the production efficiency of the equipment. Choosing equipment that can improve production efficiency can reduce production costs and increase production efficiency.

Honeycomb board is a new type of building material with characteristics such as toughness, lightweight, thermal insulation, and sound insulation, which is widely used in fields such as construction, furniture, vehicles, and packaging. Honeycomb board production line equipment is a specialized production equipment used for producing honeycomb boards. Its production process mainly includes material preparation, gluing, preheating, pressing, shearing, finished product sorting, and other links.

For the production line of plastic honeycomb panels, the extruder is one of the key equipment. It heats and melts plastic particles and extrudes them into continuous sheets or plates, providing the basic material for subsequent production. Its performance affects the quality and production efficiency of plastic sheets, and there are types such as single screw extruders and twin-screw extruders, which can be selected according to the plastic material and production requirements. For the production of aluminum honeycomb panels, it may be necessary to process aluminum alloy raw materials into specific shapes and sizes of aluminum foil and other materials, which may involve corresponding extrusion or rolling equipment.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com