Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

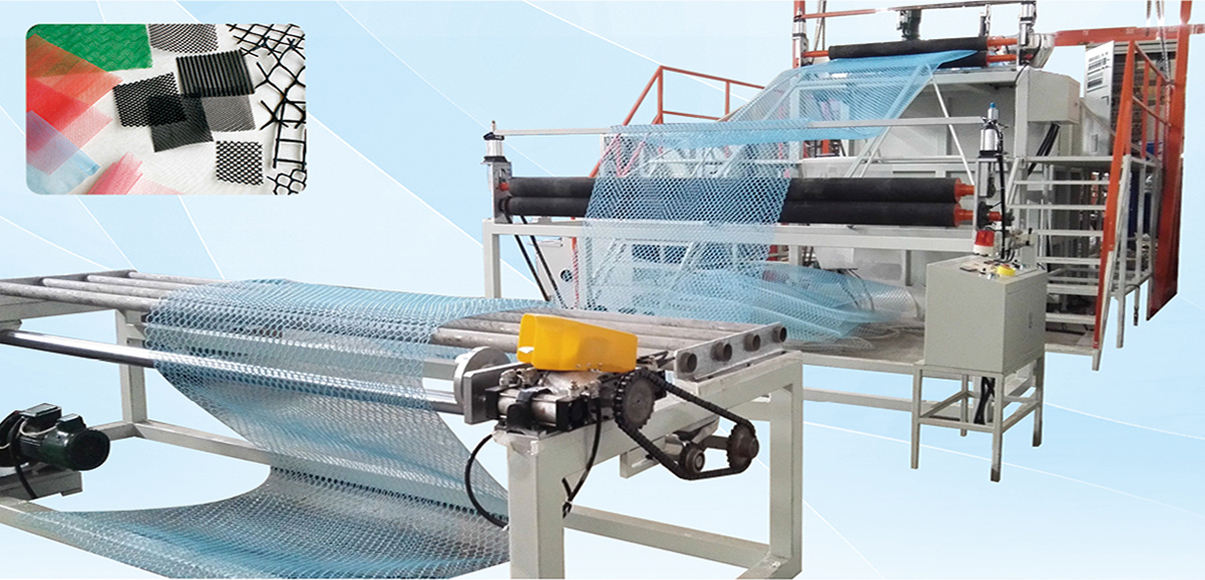

The advantages and characteristics of geogrid production line equipment are as follows: high degree of automation, which can achieve continuous production throughout the entire production process, greatly improving production efficiency; Secondly, the product quality is stable. Due to the precise control of production line equipment, the accuracy of product specifications and dimensions can be guaranteed; Once again, it saves labor costs. Compared to manual production, the geogrid production line equipment greatly reduces labor demand and lowers production costs; The production line equipment has strong adaptability and can adjust production parameters according to different customer needs to produce geogrid products of different specifications and sizes.

The cutting system is an important component of the geogrid production line equipment, which is mainly used to cut the solidified geogrid product to obtain the final product with the required size and shape. The packaging system is the next step in the equipment of the geogrid production line, mainly used to package the cut geogrid products for transportation and storage.

What details should be paid attention to when selecting equipment for the geogrid production line?

Equipment quality: Equipment quality is one of the key factors, and equipment manufacturers with a certain brand and reputation should be selected to ensure reliable equipment quality.

Production efficiency: Production efficiency directly affects the production capacity and output of the production line. Equipment with high production efficiency should be selected to improve production efficiency and reduce production costs.

Equipment stability: The stability of the equipment is crucial for the long-term stable operation of the production line, and equipment with stable structure and smooth operation should be selected.

Automation level: Production line equipment with a high degree of automation can improve production efficiency, reduce labor costs, and reduce the possibility of operational errors. Therefore, equipment with a certain degree of automation should be selected.

Cost considerations: In addition to the purchase cost of equipment, the use cost, maintenance cost, and operating cost of the equipment should also be considered, taking into account the overall cost of the equipment.

Applicability of equipment: Based on the production requirements of geogrids, select equipment suitable for the required production specifications and materials to ensure that the equipment can meet production needs.

The working principle of geogrid production line equipment is to heat, extrude, and stretch raw materials (usually plastic particles such as polypropylene or polyethylene) to produce geogrid products with a mesh structure. The specific process flow includes steps such as preheating, extrusion, stretching, cooling, and cutting. Preheating is to soften the raw material and make it easy to extrude; Extrusion is the process of squeezing softened raw materials into the desired shape; Stretching is the process of stretching extruded raw materials into a network structure; Cooling is to solidify the stretched geogrid; Cutting is the process of cutting the cooled geogrid into the required dimensions.

The mixing system is another crucial part of the geogrid production line equipment, which is mainly used to mix processed raw materials in a certain proportion to achieve the formulation of geogrid products that meet the requirements. The molding system is the core part of the geogrid production line equipment, which is mainly used to shape the mixed raw materials to form geogrid products with a certain shape and structure.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com