Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

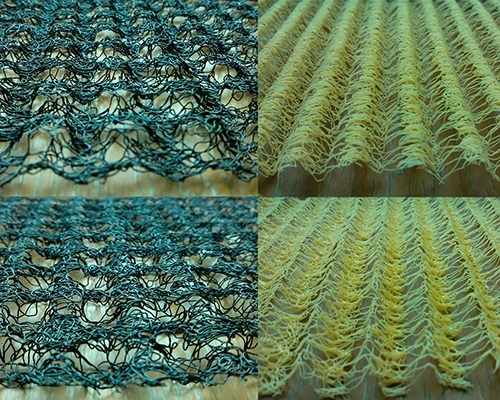

The geogrid production line equipment is a specialized equipment used for producing geogrids. Through a series of production processes and mechanical equipment coordination, various specifications and shapes of geogrids can be produced to meet the needs of different fields. With the increasing awareness of environmental protection and soil and water conservation, the production line equipment of geogrids will be more widely used and developed.

The geogrid production line equipment has the following advantages: automated production: The production line equipment adopts an automated control system, which can achieve intelligent and efficient production processes. Improving production efficiency: The efficient production process of production line equipment can greatly improve production efficiency, reduce labor costs and production cycles. Ensuring product quality: The precision control system of the production line equipment can ensure product consistency and quality stability, and reduce the rate of defective products.

What is the energy consumption of the geogrid production line equipment?

For the production process of geogrids, the processing of raw materials is a relatively energy consuming link. The main raw materials for geogrids include plastics, rubber, etc. These raw materials require processing techniques such as mixing, melting, and extrusion during the production process, which requires a large amount of electrical energy support. In addition, during the process of forming geogrids, energy consumption is also required to drive the operation of the forming equipment, ensuring that the products can be formed according to requirements.

Secondly, the drying process in the production of geogrids is also a relatively energy consuming process. In the production process of geogrids, the formed products need to be dried to ensure their quality and performance. The drying process requires a certain temperature and time, which requires the consumption of fuel energy to provide a heat source to meet the drying needs.

In addition to the two main energy consuming links mentioned above, the geogrid production line equipment also needs to consume a certain amount of electrical energy during operation to support the normal operation of the equipment and the smooth progress of the production process. For example, the conveying system, control system, lighting system, and other equipment of the equipment all require electrical energy support.

The production process of geogrid production line equipment generally includes the pre-treatment, mixing, extrusion molding, shaping, heat treatment, and other processes of raw materials. Firstly, the pre-treatment of raw materials is carried out by cleaning, screening, drying and other processes to ensure the quality and cleanliness of the raw materials. Then is the mixing of raw materials, mixing various raw materials evenly in a certain proportion to ensure the quality and performance of the grid product. Next is extrusion molding, where the mixed raw materials are extruded through an extruder to form the basic shape of a geogrid.

Geogrid is an important material used in earthwork and hydraulic engineering, widely used in river, reservoir, road, railway, port and other engineering projects. The geogrid production line is a specially designed equipment for producing geogrids. Through the automated production process of the production line, production efficiency can be improved and product quality can be guaranteed.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com