Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

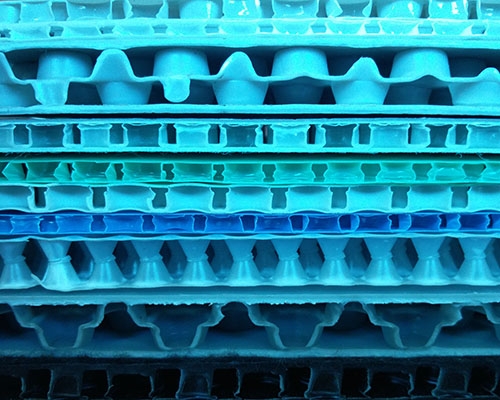

The honeycomb panel production line equipment is a key equipment for manufacturing honeycomb panels. It uses process steps such as material processing, mold forming, hot pressing curing, cutting, and testing to make raw materials into finished products. With the continuous advancement of technology, the production line equipment for honeycomb panels has achieved automated, intelligent, and efficient production methods, while emphasizing energy conservation, environmental protection, and safety, to assist the application of honeycomb panels in various fields.

The advantages of honeycomb panels are not only reflected in their performance, but also in their environmental friendliness. The honeycomb panel adopts a new honeycomb structure, which saves the use of raw materials, reduces pollution, and lowers environmental pollution. Compared with traditional building materials, honeycomb panels are lighter and thinner, reducing waste generation and disposal costs. In addition, honeycomb panels can be recycled and reused after their service life, reducing resource waste.

What factors should be considered when selecting equipment for honeycomb panel production lines?

Capacity demand: The selection of production lines should be determined based on the enterprise's capacity demand. Generally speaking, the greater the demand for production capacity, the more efficient the selected equipment and processes should be to improve production efficiency and reduce costs.

Stability and reliability of equipment: The honeycomb panel production line is a complex process that requires multiple devices to work together. Therefore, the stability and reliability of the equipment must be considered when selecting. Equipment with high stability and reliability can reduce failures and downtime, and improve production efficiency.

Process technology and innovation: With the advancement of technology, the process technology of honeycomb panel production lines is also constantly improving. When selecting, advanced process technology and innovative equipment should be considered to improve product quality and production efficiency.

Equipment adjustability and flexibility: The specifications and uses of honeycomb panels vary, so the equipment on the production line should have a certain degree of adjustability and flexibility to adapt to the production of honeycomb panels with different specifications and uses.

Energy consumption and environmental protection: In today's society, environmental protection has become an important consideration. When selecting equipment, consideration should be given to its energy consumption, selecting equipment that can save energy and reduce consumption, and complying with environmental standards to reduce environmental pollution.

The main components of the honeycomb panel production line equipment include material supply system, mold forming system, hot pressing curing system, cutting system, and detection system. The material supply system is responsible for feeding raw materials into the production line, usually using automatic feeding mechanisms and material conveying devices to achieve continuous feeding. The mold forming system is the main part that shapes raw materials through molds. The molds are usually made of metal materials and have a honeycomb like structure. The shape of the mold determines the shape and internal structure of the honeycomb panel.

The application range of honeycomb panels is very wide. In the construction industry, honeycomb panels can be used for exterior wall decoration, indoor partitions, ceilings, wall panels, etc. Due to its lightweight and high-strength characteristics, honeycomb panels are easy to install and can reduce the weight of buildings, improving their seismic performance. In the transportation industry, honeycomb panels are commonly used in fields such as aerospace, shipbuilding, and automotive. Honeycomb panels have good impact resistance and can effectively protect personal safety. In the agricultural industry, honeycomb panels can be used in places such as greenhouses, greenhouses, and breeding farms. Honeycomb panels have good thermal insulation performance, which can reduce energy consumption, improve the growth rate and yield of crops.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com