Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

The geogrid production line equipment is a type of equipment used for manufacturing geogrids. Its working principle is to process raw materials through a series of processes to produce a shaped geogrid product. The main equipment includes mixer, extruder, cooling device, cutting equipment, and stacking equipment. The organizational structure of the production line includes raw material processing area, extrusion molding area, cooling and solidification area, cutting and stacking area, and packaging area. The emergence of geogrid production line equipment has met the market demand for geogrids and provided important support for earthwork and environmental protection.

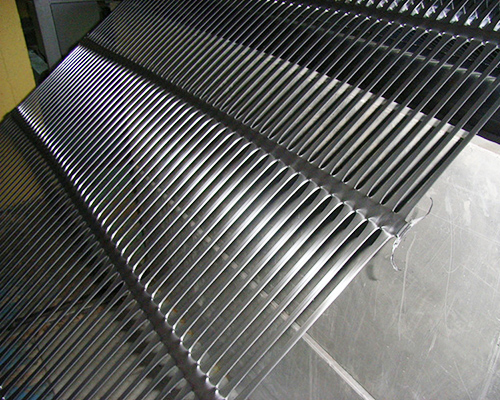

The mold head is another important equipment in the geogrid production line, used to determine the shape and size of the final product. The mold head is usually made of metal materials with specific shapes and channels. By adjusting the parameters of the mold head, different specifications of geogrid products can be produced. The extruded product is cooled by a cooling device. The cooling device usually consists of a cooling water tank, cooling water tank, cooling water circulation device, etc. Through the function of the cooling device, the product can be quickly cooled and solidified, ensuring the quality and stability of the product.

What are the new technologies for the production line equipment of geogrids?

Automation control technology: Automation control technology is one of the important technologies in the production line equipment of geogrids. By introducing devices such as PLC, sensors, and frequency converters, automated operation and control of equipment can be achieved, improving production efficiency and product quality. In addition, intelligent systems can also be used for remote monitoring and control, improving the reliability and uniformity of the production line.

Precision mold technology: Precision mold technology is one of the key technologies in the production line equipment of geogrids. Through advanced design and manufacturing technology, grid products with precise dimensions, sturdy structure, and beautiful appearance can be produced. The use of precision molds can also achieve rapid mold replacement, increasing the flexibility and production capacity of the production line.

Application of new materials: The application of new materials is also one of the important technologies in the production line equipment of geogrids. For example, using high-strength, corrosion-resistant, and wear-resistant composite materials to make molds and forming equipment can extend the service life of the equipment and reduce the frequency of equipment maintenance and replacement. In addition, new materials can be introduced to produce grille products, improving their performance and durability.

The main equipment of the geogrid production line includes mixer, extruder, cooling device, cutting equipment, and stacking equipment. The mixer is mainly used to mix raw materials to ensure uniform mixing. The extruder is the core equipment of the entire production line, which extrudes and shapes uniformly mixed materials. The cooling device is used to cool the extruded geogrid, solidifying and strengthening it. Cutting equipment is mainly used to cut geogrids into appropriate sizes. Stacking equipment is used to stack and package cut geogrids.

Plastic forming is the core process of the geogrid production line. The preheated raw materials are processed through a series of extrusion, plasticization, pressure regulation, and mold forming steps through an extruder to form a structured geogrid product. During the molding process, the temperature and pressure of the extruder need to be strictly controlled to ensure the quality and shape of the product.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com