Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

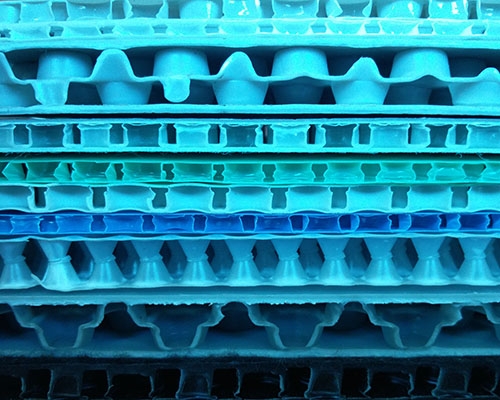

The honeycomb panel production line equipment can adapt to different user needs by adjusting materials, honeycomb shape, panel density, and production specifications. This flexibility and adaptability are one of the excellent characteristics of honeycomb panel production line equipment, and also an important guarantee for continuously meeting the needs of different fields. The honeycomb panel production line equipment can adjust production specifications according to different user needs, including panel width, length, thickness, and honeycomb aperture. By adjusting production specifications, honeycomb panel products can be created that are more suitable for different scenarios.

Honeycomb panel production line equipment is a type of production equipment specifically used for producing honeycomb panels, which can produce clear and beautiful honeycomb panels. It is a very important equipment in various industries such as construction and compression materials. In the process of producing honeycomb panels, the production line equipment can be adjusted to a certain extent to meet the needs of different industries or users, which is a very important production method.

How to choose cost-effective honeycomb panel production line equipment?

1. Equipment production capacity

When selecting equipment for the honeycomb panel production line, it is necessary to consider the production capacity of the equipment. The production capacity of equipment should be selected based on production needs, and cannot be too small or too large. If the production capacity of the equipment is too small, it will lead to low production efficiency and inability to meet market demand; If the production capacity of the equipment is too large, it will waste production resources and increase the operating cost of the equipment. Therefore, it is necessary to choose honeycomb panel production line equipment that is suitable for one's own production requirements.

2. Equipment production technology

Production technology is the core of production line equipment and an important factor affecting the cost-effectiveness of equipment. The current honeycomb panel production lines on the market have different equipment technologies and manufacturing processes, resulting in significant differences in cost and quality. Therefore, when choosing production line equipment with high cost-effectiveness, attention should be paid to the production technology of the equipment, such as the degree of automation, intelligence, work efficiency, and production accuracy of the production line.

3. Equipment materials used

When selecting equipment for the honeycomb panel production line, it is also necessary to consider the materials used in the equipment. The materials used in the equipment will have a significant impact on the service life and production efficiency of the equipment. When selecting materials, factors such as stability, ease of operation, and durability should be considered. Therefore, when choosing cost-effective production line equipment, it is necessary to choose equipment with better quality, while also paying attention to the after-sales service and production cycle of the equipment.

The honeycomb board production line equipment mainly consists of the following components: a paper press: rolls cardboard into a certain thickness onto the production line, and after pressing, presses the cardboard into a certain shape and size of honeycomb board. Drying room: Place the pressed honeycomb board into the drying room for drying treatment to ensure its surface dryness and quality. Cutting machine: Cut the dried honeycomb board into the required size to meet the needs of different industries.

The honeycomb board making machine is the core equipment in the production line, mainly used to make honeycomb boards from raw materials (such as paper, aluminum foil, etc.) after a series of processing steps. Production machines are usually divided into two types: automated and semi automated. The higher the level of automation, the higher the production efficiency and the more stable the quality of the honeycomb panels produced. The honeycomb panel stacking and forming machine is a device used to stack honeycomb panel units in a certain order into a whole honeycomb panel. Through stacking and forming machines, we can quickly produce honeycomb panels of different sizes and shapes, with very high production efficiency.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com