Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

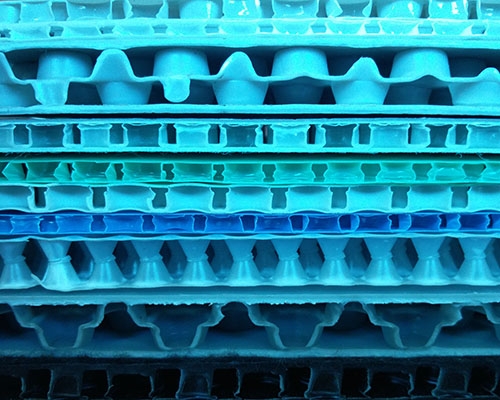

The honeycomb panel production line equipment is a complex and massive system that requires close cooperation and collaboration among various devices. By gathering so many devices, a complete production line can be formed, greatly improving the production efficiency of honeycomb panels and driving the rapid development of related industries.

The honeycomb board foaming machine is the core equipment for producing honeycomb boards. It uses polymer foaming technology to inject foaming substances into the core layer of the honeycomb board, forming a three-dimensional hollow structure. The foaming machine needs to strictly control parameters such as temperature and pressure during the production process to ensure the quality and performance of the honeycomb board. The pressing machine is the process of pressing the outer and core materials of honeycomb panels through high temperature and high pressure to form a whole.

Equipment layout of honeycomb panel production line

The honeycomb panel production line mainly includes several areas such as raw material processing area, embossing area, coating area, oven area, cutting area, packaging area, etc. These areas need to have a reasonable layout in the production line to facilitate material flow and processing.

The raw material processing area is the area responsible for processing raw materials, mainly including equipment such as cardboard processing machines and die-cutting machines.

The embossing area mainly processes the surface of honeycomb panels to achieve beautification, protection, and other functions. This requires equipment such as embossing machines.

The coating area is mainly used for coating treatment to achieve a certain level of smoothness and stain resistance on the surface of the honeycomb panel. This requires equipment such as automatic coating machines.

The oven area is used to cure the coating material to ensure its hardness and durability. This requires equipment such as an oven.

The cutting area mainly customizes honeycomb panels to meet the needs of different markets and customers. Laser cutting machines, CNC cutting machines, and other equipment are required here.

The packaging area is mainly used for packaging finished products for operation and transportation. This requires equipment such as an automatic packaging machine.

The honeycomb panel production line is an efficient and intelligent industrial production equipment. The honeycomb panels produced using this production line equipment have the advantages of stable quality, low cost, environmental protection and energy conservation, and are widely used in fields such as construction, transportation, aviation, water conservancy, and environmental protection.

The honeycomb panel production line equipment refers to the entire equipment chain used to produce honeycomb panels, including all machinery, tools, and auxiliary equipment on the production line. Honeycomb board is a new type of lightweight and high-strength composite material with high mechanical and thermal properties, which has a wide range of applications, including construction, aviation, automotive, e-commerce and other fields.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com