Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

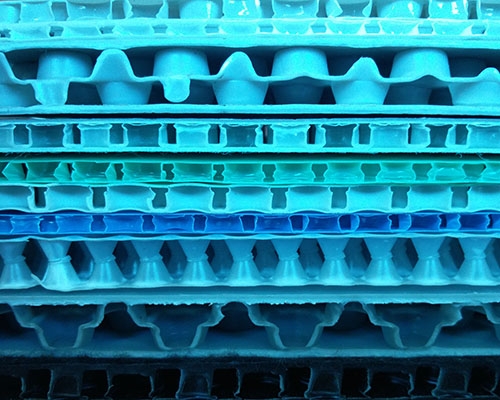

The honeycomb panel produced by the honeycomb panel production line equipment is a panel made of two thinner panels firmly bonded to both sides of a thick honeycomb core material, also known as a honeycomb sandwich structure. In addition, honeycomb panels also refer to panels that weld a large number of cutoff waveguides together to form a cutoff waveguide array, forming a large opening area and preventing electromagnetic wave leakage. Honeycomb panels are divided into cushioning honeycomb panels and packaging honeycomb panels according to their functions. Due to its structure, it can improve compressive strength, while paper honeycomb panels can more effectively reduce costs.

Aluminum honeycomb panels use metal plates as panels, which are cut and classified for bending. This involves processing and shaping, followed by pre-treatment, welding and polishing the contours of the aluminum honeycomb panel and edges. After using adhesive bonding, the aluminum honeycomb panel is assembled and merged. After pre-treatment, the next process of hanging is spraying, which can be freely selected from fluorocarbon or polyester.

Category of honeycomb panels produced by honeycomb panel production line equipment:

According to product usage, it can be divided into two categories:

1. Applied to the interior parts of passenger cars such as trunk covers, trunk partitions, trunk carpet substrates, side wall decorative panels, and ceilings.

2. Applied to the production of various high-strength packaging boxes, such as logistics transportation turnover boxes, replacing traditional wooden boxes.

Honeycomb panels generally have apertures of 8mm, 16mm, and 32mm, and paper honeycomb panels weigh 280g/1 square meter. Paper honeycomb boards can be used to make various types of pallets, liners, packaging boards, packaging boxes, etc. Paper honeycomb board is a new type of green packaging material that has emerged in developed countries this year to save resources, protect the ecological environment, and have low costs. It has many advantages such as light, strong, stable, thermal insulation, insulation, and shock resistance. In terms of volume, it can range from 0.4 cubic meters to 6 cubic meters. The load is 1 kilogram light and 2500 kilograms heavy.

The surface of the aluminum honeycomb panel is made of aluminum alloy sheet treated with fluorocarbon rolling coating, with aluminum honeycomb in the middle that meets the aviation standards of China, the United States, and Russia. The special composite process of cold pressing and hot pressing technology is used, making the aluminum honeycomb panel have advantages such as light weight, sound insulation, heat insulation, fire protection, environmental protection, non fragility, strong rigidity, and non deformation. The high flatness board is composed of two layers of aluminum plates sandwiched between them with high-strength mild aluminum honeycomb core material, forming an ideal board with high flatness and minimal deformation.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com