Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

The surface coatings of aluminum honeycomb panels produced by honeycomb panel production line equipment are fluorocarbon baking paint, polyester powder spraying, acrylic baking paint, fluorocarbon or polyester roller coating decoration. Due to the fact that aluminum honeycomb panels are equivalent to countless I-beam structures, they are endowed with greater rigid bending strength and smaller bending deformation. The honeycomb panel has a high flatness, which is much better than single aluminum panel and aluminum plastic panel. It can manufacture larger size panels (1.5m × 10m), meeting the designer's design concept. In addition, due to the ability of aluminum honeycomb panels to process shapes such as "L", "U", and single curved arcs, they can meet the requirements for irregular shapes in architectural decoration.

Honeycomb wall panels have high strength, flat surface, and are not easily deformed. The honeycomb sandwich structure is approximately isotropic, has good structural stability, and is not easily deformed. Its outstanding compressive and bending resistance are important characteristics required for box packaging materials. The front of ordinary honeycomb cardboard can withstand a pressure of 2-5kg per square centimeter, which is 5-10 times the compressive strength of ordinary corrugated cardboard. The bending strength of ordinary honeycomb cardboard is 2-5 times that of reinforced corrugated cardboard, and 5-30 times that of ordinary corrugated cardboard.

What colors are the honeycomb panels produced by the honeycomb panel production line equipment

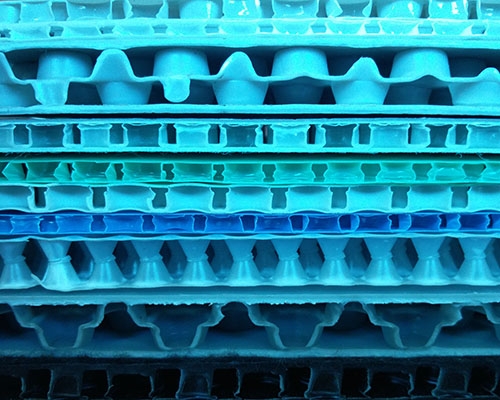

The common colors of honeycomb panels are blue and black, and manufacturers generally have inventory of both colors. If customers require honeycomb panels of other colors, they may also have inventory, but the thickness of the honeycomb panels in inventory may not be complete. For example, if only 5mm thick red or 3mm thick red is needed, it will be produced and the lead time will be longer. If the customer is in a hurry, choose a blue or black honeycomb board!

The aluminum honeycomb panel also has good impact resistance and shock absorption performance. When our panel is subjected to an out of plane impact, the impact force it receives will be converted into the plastic deformation energy of the honeycomb core, in order to effectively absorb the impact energy. The honeycomb panel manufacturer explains that the toughness of aluminum honeycomb panels has strong impact resistance, which can absorb a large part of energy through deformation, making the overall product more sturdy and physically stable.

Aluminum honeycomb panels are divided into buffering aluminum honeycomb panels and packaging aluminum honeycomb panels according to their functions. Due to its special structure, it can improve compressive strength and reduce costs with plastic aluminum honeycomb panels. The aperture of aluminum honeycomb panels is generally divided into: (circular) 6mm and 8mm; (Hexagonal) 3.6MM, 6MM, 8MM sizes, PC honeycomb core 8MM: 07KG/1 square meter. Plastic aluminum honeycomb panels can be used to make billboards, suspended ceilings, decorative panels, light boxes, etc. Plastic aluminum honeycomb panel is a new type of green decorative material that has emerged in developed countries this year to save resources, protect the ecological environment, and have low costs. It has many advantages such as light, strong, stable, thermal insulation, and insulation.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com