Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

The installation method of aluminum honeycomb panel for wall decoration is generally the same as that of aluminum veneer, and the correct installation and flatness performance of aluminum honeycomb panel itself ensure its decorative effect. Aluminum honeycomb panels have the characteristics of low density, good sound insulation, thermal insulation, shock absorption, lightweight, energy-saving, and convenient installation. The installation method of aluminum honeycomb panels is often used for indoor walls and suspended ceilings, and its installation accuracy standard is higher than that of external walls. Therefore, it is necessary to ensure the correct installation of aluminum honeycomb panels.

Thick honeycomb panels are easy to install, with fewer auxiliary materials, saving materials, time, and effort. The total installation cost is low, and they are superior to pure stone in terms of weight, strength, flatness, and sound insulation. Therefore, they are more suitable for high-rise and building curtain wall or interior wall decoration. It can eliminate the risk of thin porcelain plate detachment caused by construction quality. The bonding strength of traditional brick bonding mortar is about. 4MPa, while the shear strength of the special adhesive for this system can reach over 15MPa, and it has excellent wind pressure resistance.

Judging the quality of honeycomb panels produced by honeycomb panel production line equipment

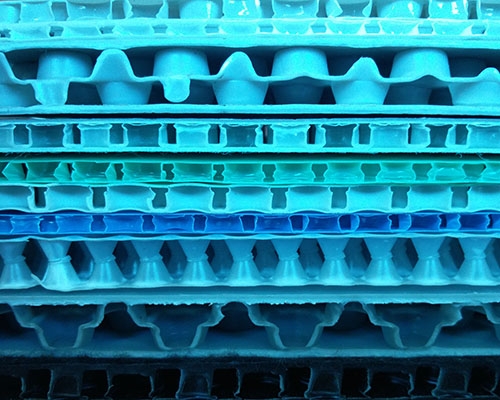

1. The thickness of the honeycomb core is 7mm~9mm, and the honeycomb core in the ceiling generally adopts a side length of 5-6mm honeycomb core; The denser the density, the stronger the resilience to external forces, the more support points, and the smoother the board. It can effectively absorb impact energy, play a role in shock absorption and collision prevention, thereby protecting the wall from damage.

2. Check if the manufacturer has a supporting construction plan that meets the product requirements, as well as a formal national quality inspection report and environmental protection label.

3. Choose native aluminum as the aluminum material, which is not prone to bumps, pits, and other phenomena, to ensure a smooth surface of the board.

Honeycomb wall panels have high strength, flat surface, and are not easily deformed. The honeycomb sandwich structure is approximately isotropic, has good structural stability, and is not easily deformed. Its outstanding compressive and bending resistance are important characteristics required for box packaging materials. The front of ordinary honeycomb cardboard can withstand a pressure of 2-5kg per square centimeter, which is 5-10 times the compressive strength of ordinary corrugated cardboard. The bending strength of ordinary honeycomb cardboard is 2-5 times that of reinforced corrugated cardboard, and 5-30 times that of ordinary corrugated cardboard.

The aluminum honeycomb panel also has good impact resistance and shock absorption performance. When our panel is subjected to an out of plane impact, the impact force it receives will be converted into the plastic deformation energy of the honeycomb core, in order to effectively absorb the impact energy. The honeycomb panel manufacturer explains that the toughness of aluminum honeycomb panels has strong impact resistance, which can absorb a large part of energy through deformation, making the overall product more sturdy and physically stable.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com