Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

In the construction field, aluminum honeycomb panels are often used to make the ceilings of subway stations, large shopping malls and conference rooms, as curtain walls and roofs of high-rise buildings, as well as screens, soundproof panels and portable activity rooms of banks and hotels. Aluminum honeycomb panels not only have good decorative effect, but also can use the characteristics of vibration and energy absorption of honeycomb panels to reduce casualties and property losses caused by earthquakes.

Honeycomb board has stable structural performance and is not easy to deform. Its outstanding compressive and deformation resistance is a very important feature of box packaging materials. Ordinary honeycomb board can withstand 5-10 times the compressive capacity of ordinary corrugated board, and its bending strength is 5-30 times that of ordinary corrugated board. Therefore, honeycomb board has high strength, very flat surface and is not easy to deform.

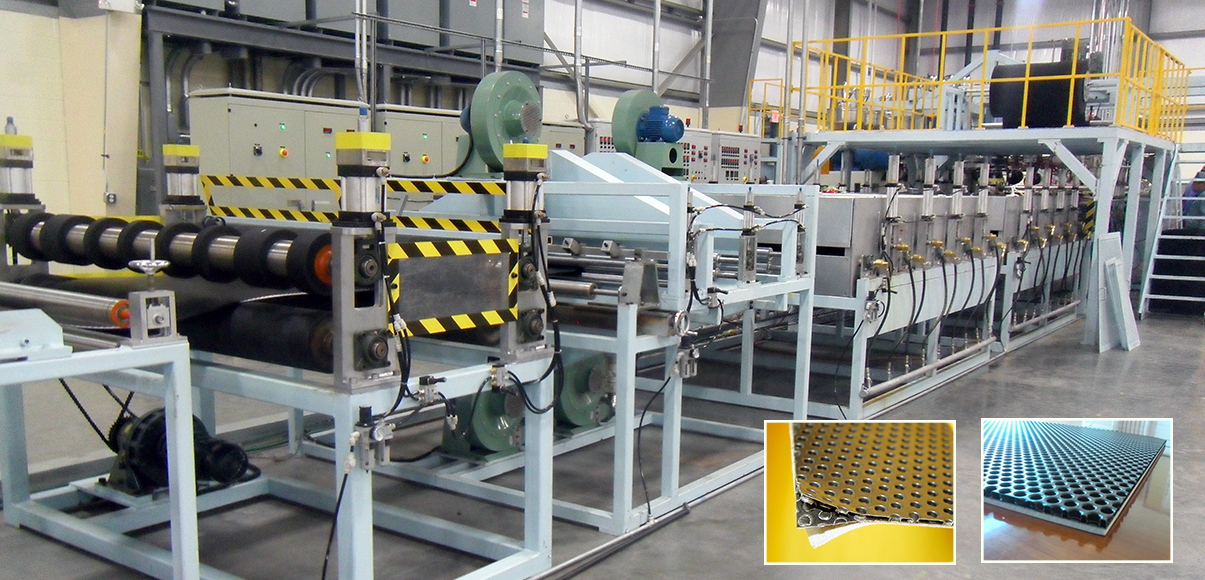

Honeycomb panel produced by honeycomb panel production line equipment is a green building material

The center of the honeycomb plate is aluminum hexagonal honeycomb, with a small density (about 3 ~ 7kg per square meter), which is 1/5 of the weight of wood plate with the same thickness and area, 1/6 of glass, 1/7 of aluminum and 1/10 of steel plate. The total thickness is 15mm, the panel is 1.0mm, and the bottom plate is 0.8mm aluminum honeycomb plate, with a weight of only 6kg / m2.

The interconnected honeycomb cores are like countless I-beams. The core layer is distributed and fixed in the whole plate surface, which is not easy to shear, making the plate more stable, more resistant to bending and compression. Its wind pressure resistance is much higher than that of aluminum-plastic plate and aluminum veneer, and it is not easy to deform and has good flatness. Even if the honeycomb plate is large, it can achieve high flatness. Because the honeycomb cores in the honeycomb composite plate are separated into many closed chambers, It prevents the air flow and greatly hinders the heat and sound waves. Therefore, it has the effect of heat insulation, heat preservation and sound insulation.

For 100-3200hz sound source, the thermal conductivity can reach 20~30db, and the thermal conductivity is 0.104-0.130w/m.k. therefore, the energy absorption capacity of aluminum honeycomb plate is 150-3500kj/m ² It is an ideal energy-saving material.

The stainless steel honeycomb panel is an environmental protection material that uses advanced aviation technology and self-developed automation equipment to compound high-quality stainless steel plate and aluminum honeycomb core into thermal insulation, sound insulation and flame retardant. The stainless steel honeycomb panel series products have rich specifications and can provide a variety of panel shapes, especially suitable for the application of large panels. Its unique charm lies in the larger, smoother, more uniform color, richer color and wider range of application.

Honeycomb panel is a panel made of two thin panels firmly bonded to both sides of a thick honeycomb core material, also known as honeycomb sandwich structure. In addition, a honeycomb panel also refers to a panel that welds a large number of cut-off waveguides together to form a cut-off waveguide array, forming a large opening area and preventing electromagnetic wave leakage. A kind of high-grade building decoration material for exterior wall, which was mainly used in the aviation field in the past, is now widely used in home decoration buildings.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com