Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

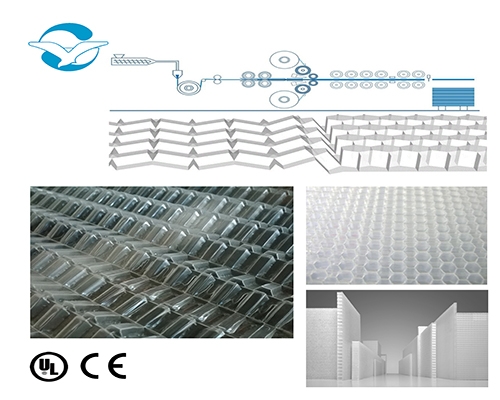

Inspired by the honeycomb, the resistance of honeycomb structure to extrusion force is much higher than that of any circle or square, and aluminum honeycomb plate honeycomb structure materials began to appear. Aluminum honeycomb panels not only have excellent performance in large-scale and flatness, but also have many choices in shape, surface treatment, color, installation system, etc. It has been popular in the market in recent years.

The honeycomb plate produced by the honeycomb plate production line equipment generally adopts fluorocarbon roller coated plate as the panel. The important point of fluorocarbon roller coated plate is that continuous roller coating process is adopted. The coating of the plate is completed at one time to ensure that the product has no color difference, good coating smoothness and reliable quality. At the same time, it can maintain the bright color of the external wall of the building for a long time. After long-term exposure to the sun and rain or industrial waste gas pollution, it is obvious that the roller coated plate is cleaner and brighter than the spray coated plate, and has good adhesion and weather resistance. It is a material recognized by architects all over the world. Corrosion resistance: the surface of honeycomb plate has strong corrosion resistance after being treated with fluorocarbon resin with strong corrosion resistance.

The paper core of the honeycomb board is bonded with the upper and lower panels, and adhesive and gluing equipment are required for bonding. Gluing equipment is divided into single-sided gluing machine and double-sided gluing machine. The gluing equipment shall ensure that the gluing amount on the plate is uniform and the gluing amount can be accurately controlled to reach the set glue amount per square meter, which are two important performance requirements. Cots are the key components of gluing equipment. The material of cots and the running accuracy of cots are directly related to the quality of gluing. At present, the diameter of the domestic common glue coating roller is 190mm, the power of the glue coating machine is, and the production speed is 20m/min.

At present, there are some honeycomb plate bonding combined equipment in China. The front section of the combined equipment is a conveying roller. The frame with plate core will be uniformly coated with adhesive through the double-sided gluing equipment, and then the panel will be covered. After that, it will enter the rear rolling equipment to pressurize, realizing the pressing of honeycomb paper core and upper and lower surface plates.

Aluminum honeycomb panel has good performance and obvious advantages. Greater specific bending stiffness and higher specific bending strength, i.e. light weight and high strength; The flatness is very good, which can meet the requirements of large separation of building curtain wall, and achieve good architectural performance with less building components; Various surface treatments are available; Good fire resistance; It has good sound absorption, sound insulation, heat insulation, shockproof and other functions; Good environmental protection, 100% recycling.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com