Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

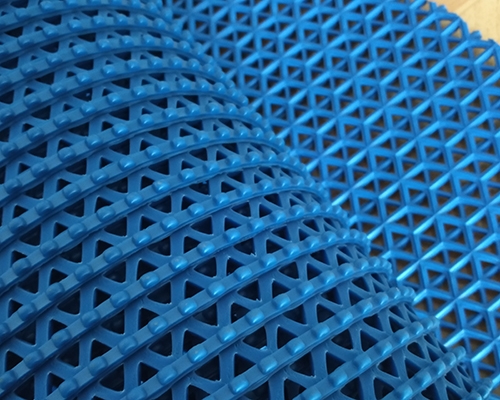

Geogrid production line equipment, geogrid is often used as reinforcement of reinforced soil structure or composite material. 1. high strength and small deformation; 2. small creep; 3. corrosion resistance and long service life: the steel plastic geogrid takes the plastic material as the protective layer, supplemented by various additives to make it have anti-aging and oxidation properties, and can resist the corrosion of acid, alkali, salt and other harsh environments.

At present, 90% of the biaxial stretching film production lines are applicable to the production of packaging film, and 20% are special production lines for special films, that is, special production lines. Except for the devices specially designed to meet the process requirements, other parts are basically common with the packaging film stretching equipment, and this part is also the majority. The main reason is that it is unclear how the process affects the process parameters of the equipment and how to eliminate these effects.

The use effect of the geogrid production line equipment and the glass fiber grid is closely related to the treatment of the paved pavement. Before paving, the substances on the pavement that may affect the bonding strength between the grid and the bottom layer, such as grease, paint, sealing material, water stains, dirt, etc., must be completely removed to make the paved surface clean and dry. The pressure sensitive back abdomen on the glass fiber grating is a water-soluble substance. If there is water trace on the pavement, it should be paved after the pavement is dry. Before the grid is laid, tack coat oil shall be sprayed. If emulsified asphalt is used for tack coat oil, the grid shall be laid after complete demulsification and drying.

According to different materials, geogrids are divided into plastic geogrids (unidirectional tensile grid, bidirectional tensile grid, three-dimensional tensile grid), glass fiber geogrids (glass fiber grid), polyester warp knitted geogrids (polyester grid), steel plastic composite geogrids, PP welded geogrids, and pet welded geogrids. The geogrid shall be laid on the leveled lower bearing layer according to the design width. During paving, it shall be straightened, smooth, and close to the lower bearing layer without distortion, fold or overlap. The overlap shall be fixed with U-shaped nails or connectors. During the laying of geogrid, the direction with high main strength of reinforcement shall be vertical to the embankment axis, and the overlapping length (longitudinal) of each piece shall not be less than 15 cm, and shall be fixed with U-shaped nails or connectors. The spacing shall be 1.0m, and the transverse overlapping length shall be 30 ~ 90 cm, The overlapping position shall be fixed with staples or nylon ropes.

For the equipment of the geogrid production line, after the termination edge of the geogrid is connected with the nylon rope, the winch of the drum is used to roll up and recover. The overlap between each geogrid is required to be spliced together with a special binding tape every 50cm. The operator binds and splices while the winch rolls up and recovers until the splicing of the geogrid in this section is completed.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com