Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

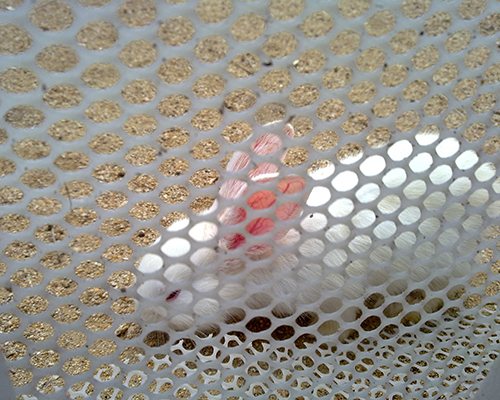

Honeycomb paperboard is of core structure, with excellent cushioning and vibration isolation function, close to EPS. Good heat and sound insulation performance. The honeycomb hole of the honeycomb core is a closed structure, which is filled with air and does not circulate with each other. Therefore, it has good heat insulation and sound insulation performance. The strength and stiffness are easy to adjust. Light weight: PP (polypropylene) plastic honeycomb plate is about 1/12 of the mass of water accumulated in the same body and 1/32 of aluminum, which can greatly reduce the load of buildings, and the weight of decorative materials, home furnishings, kitchenware, cars, ships and light rail vehicles.

Sound insulation and heat insulation: the honeycomb panel production line equipment has good sound insulation and heat insulation performance because the air layer between the two panels is divided into many closed gaps by honeycomb, and PP (polypropylene) plastic and PC (polycarbonate) plastic are not good conductors of heat, which greatly limits the transmission of sound and heat.

In the oxidation process, different standards for the use of the product are determined according to the thickness and density of the oxide film. For example, the anodized aluminum plate will not change color, corrode, oxidize or rust in the room for a long time. Anodic aluminum oxide products with a film thickness of more than 10um can be used outdoors and can be exposed to the sun for a long time without discoloration.

Anodizing has strong applicability and wide applications. It is suitable for metal aluminum ceiling, curtain wall panel, aluminum plastic panel, fire board, honeycomb aluminum panel, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc. As a new environmental protection packaging material, honeycomb paperboard has been more and more widely used.

At present, the research of domestic and foreign scholars mainly focuses on the mechanical properties of honeycomb paperboard products, and rarely involves its production process and equipment. This paper studies the production equipment and processing technology of honeycomb paperboard. The manufacturing process and principle of honeycomb paperboard were described. The paper core production of honeycomb paperboard is the key technology. Therefore, the processing principle of paper core manufacturing equipment at home and abroad is analyzed, and their advantages and disadvantages are compared. The processing mode that meets the needs of domestic honeycomb paperboard manufacturers is obtained, which plays a certain role in further promoting the development of honeycomb paperboard processing technology.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com