Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

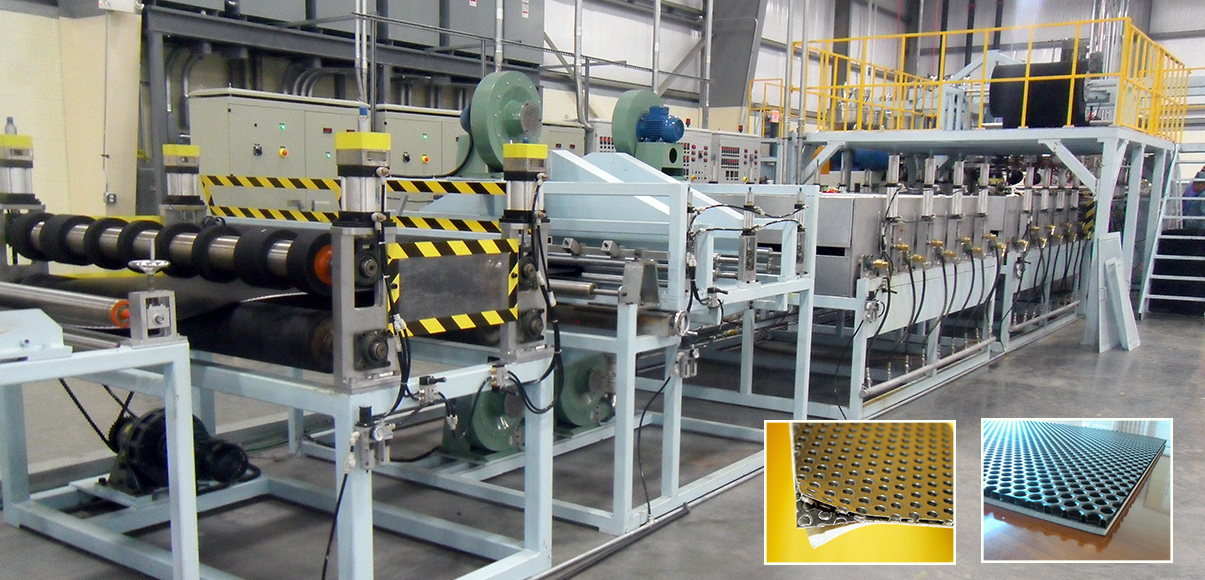

Honeycomb board, as a lightweight and high-strength composite material, is widely used in fields such as building decoration, transportation, aerospace, etc. When purchasing honeycomb panel production line equipment, it is necessary to comprehensively consider multiple factors to ensure investment efficiency and production efficiency. The following are the key issues that need to be noted during the procurement process of honeycomb panel production line equipment:

1、 Clarify production requirements and technical parameters

Product specifications and production capacity requirements

Clearly define the size range of honeycomb panels to be produced (length, width, thickness)

Determine the type of core material (aluminum honeycomb, paper honeycomb, plastic honeycomb, etc.)

Calculate daily/monthly/annual production capacity demand and consider future expansion possibilities

Evaluate product accuracy requirements (flatness, diagonal tolerance, etc.)

Process route selection

Determine whether to use a continuous production line or an intermittent production method

Choose the appropriate bonding process (hot pressing, cold pressing, or room temperature curing)

Consider surface treatment requirements (spraying, coating, anodizing, etc.)

degree of automation

Evaluate the cost-benefit ratio of manual operation and automated production

Determine the control system level (PLC, industrial PC, or higher end configuration)

Consider the integration requirements of data collection and production management systems

2、 Equipment selection and technical evaluation

Core equipment performance

Honeycomb core deployment equipment: deployment speed, precision control, waste rate

Adhesive coating system: compatibility of adhesive types, uniformity of coating, precision of adhesive quantity control

Composite press: pressure uniformity, temperature control accuracy, pressure holding time adjustment range

Cutting equipment: cutting accuracy, tool life, and ability to process irregular shapes

Integrity of production line configuration

Check the compatibility of equipment before and after the process (such as pre-processing and post-processing equipment)

Evaluate the coherence and efficiency of the material conveying system

Confirm the completeness of auxiliary equipment (dust removal, exhaust gas treatment, etc.)

Evaluation of technical progressiveness

Compare the advantages and disadvantages of technical solutions from different suppliers

Examine the energy consumption indicators and environmental performance of equipment

Understand the equipment upgrade space and the application of new technologies

3、 Supplier selection and business considerations

Supplier Qualification Evaluation

Verify the qualification documents such as business license and production license of the enterprise

Understand the industry reputation and the actual operation of implemented cases

Evaluate the strength of the technical team and the coverage of the after-sales service network

Price and Payment Terms

Obtain detailed quotations from multiple suppliers and conduct comparative analysis

Clearly define the payment method, stage, and ratio (usually in stages of 3:4:2:1)

Understand the details of additional fees such as taxes, transportation, and installation

Delivery, Installation, and Debugging

Confirm the delivery date and default terms of the equipment

Clearly define the installation and debugging cycle and division of responsibilities

Agreed acceptance criteria and procedures (no-load/load testing, product compliance, etc.)

4、 Quality Control and Acceptance Standards

Equipment manufacturing quality monitoring

Request material certification and testing reports for key components

Arrange mid-term factory inspection or key node acceptance when necessary

Verify the brand and quality of core components such as electrical components and hydraulic systems

Performance acceptance testing

Develop a detailed FAT (Factory Acceptance Test) plan

Conduct a continuous 72 hour fault free operation test

Verify equipment processing accuracy and product qualification rate indicators

Documents and Training Requirements

Request complete technical documentation (mechanical/electrical drawings, operation/maintenance manuals)

Confirm the training content and duration (operation, maintenance, troubleshooting, etc.)

Request to provide a list of vulnerable parts and a recommended spare parts catalog

5、 After sales service and long-term cooperation

Warranty terms

Clearly define the warranty period (usually 1-2 years) and scope

Understand the special warranty policy for key components

Confirm response time and fault handling process

Technical Support

Evaluate the remote diagnostic capability of suppliers

Understand software upgrade and process improvement support policies

Confirm the mechanism for updating technical data

spare parts supply

Evaluate the inventory status and supply cycle of commonly used spare parts

Negotiate spare parts price discount mechanism

Consider the necessity of establishing a local spare parts warehouse

6、 Other important precautions

Factory buildings and infrastructure

Confirm the installation space of the equipment and the load-bearing requirements of the factory building

Check the power supply (voltage, capacity, stability)

Assess the demand for auxiliary facilities such as compressed air and circulating water

Safety and Environmental Compliance

Verify the completeness of the safety protection devices of the equipment

Understand environmental indicators such as noise, exhaust gas, and waste materials

Confirm compliance with local safety production and environmental regulations

Future scalability

Consider the potential for device compatibility in future product development

Evaluate the convenience and cost of expanding the production line

Understand the impact of industry technology development trends on equipment

The procurement of honeycomb panel production line equipment is a complex system engineering that requires comprehensive consideration from multiple dimensions such as technology, economy, and management. It is recommended to establish a special team composed of departments such as technology, procurement, and production to develop detailed procurement plans and evaluation standards. At the same time, conducting on-site inspections of the production sites of existing customers of suppliers and obtaining first-hand operational data will provide important references for decision-making. Through a scientifically rigorous procurement process, it can be ensured that the selected equipment can meet current production needs while also having good long-term value, creating a sustainable competitive advantage for the enterprise.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com