Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

Company name: Dalian Plastics Research Institute Co., Ltd

Telephone:+86-411-66177850

18841186255

Fax:+86-411-86601784

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning

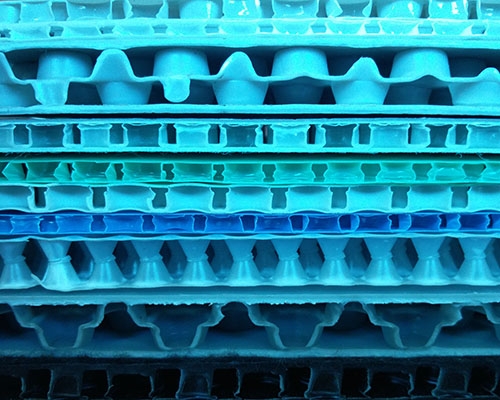

Honeycomb panels, as a representative of lightweight composite materials, are widely used in fields such as aerospace, rail transportation, and building decoration. The technical parameters of honeycomb panel production line equipment directly determine product quality and production efficiency. This article will provide a detailed analysis from three dimensions: core parameters, supporting systems, and selection points.

1、 Core equipment technical parameter system

(1) Substrate processing unit

Uncoiler parameters

Maximum roll diameter: usually 1500-2500mm (for construction) or 3000mm (for industrial grade)

Material compatibility: The thickness range (0.1-1.2mm) applicable to aluminum/stainless steel coils should be specified

Tension control accuracy: high-end equipment can achieve ± 1%, ordinary equipment can achieve ± 3%

Surface treatment system

The length of the cleaning section ranges from 6 to 12 meters, which directly affects the treatment effect

Passivation film weight: Building boards require ≥ 1.0mg/m ² (chromate treatment)

Drying temperature: adjustable from 180-220 ℃, temperature uniformity ± 5 ℃

(2) Forming composite section

Honeycomb core deployment device

Unfolding speed: 15-30m/min (synchronized with the production line)

Correction accuracy: ± 0.5mm (laser detection system)

Core grid size tolerance: ± 0.05mm (hexagonal standard grid)

Hot press laminating machine

Working pressure: 8-15MPa adjustable (hydraulic system pressure)

Heating plate temperature difference: ± 2 ℃ (imported hot oil mold temperature machine)

Pressure holding time: 90-180 seconds (adjusted according to the type of adhesive)

(3) Post processing system

CNC cutting center

Positioning accuracy: ± 0.1mm/m (fully closed-loop servo system)

Maximum processing thickness: 100mm (heavy-duty gantry type)

Tool storage capacity: 12-24 workstations (automatic tool changing system)

2、 Interpretation of Key Performance Indicators

(1) Capacity related parameters

Design cycle: Single shift (8h) production capacity of 200-500 ㎡ (building board)

Mold changing time: ≤ 15 minutes (quick clamping device)

Equipment OEE: ≥ 85% (international first-line brand standard)

(2) Quality assurance parameters

Flatness of board surface: ≤ 1mm/m ² (laser detection)

Peel strength: ≥ 4N/mm (EN standard)

Fire rating: A2 level (SGS testing report required)

(3) Energy consumption indicators

Total installed power: 350-600kW (including auxiliary equipment)

Compressed air consumption: 0.6m ³/ min@0.7MPa

Thermal efficiency: ≥ 75% (waste heat recovery system)

3、 Key points for in-depth analysis of technical parameters

(1) Parameter correlation verification

Speed matching principle: The unwinding speed should be 5-10% faster than the composite section to prevent excessive tension

Temperature gradient control: matching degree between heating plate temperature difference and adhesive activation temperature

Pressure thickness curve: pressure compensation coefficients corresponding to different plate thicknesses

(2) Hidden parameter recognition

Equipment rigidity index: rack deformation should be less than 0.05mm/10 ton pressure

Control system response: PLC scanning cycle ≤ 1ms (real-time control requirement)

Bearing life: Key parts should be ≥ 30000 hours (SKF/FAG standard)

4、 Selection decision matrix

Parameter verification method

No load test: Increase the speed to 120% of the rated value to verify mechanical stability

Material testing: Continuous 8-hour production to verify parameter stability

Restricted testing: Verification of processing capability for thin/thick materials

Note: In actual selection, product positioning should be taken into account (such as significant differences in parameters between building decorative panels and aviation panels). It is recommended to organize a joint review of processes, equipment, and procurement, with a focus on the verifiability and sustained stability of parameters.

Address: No.18 Fenghenan Road,Lvshunkou District,Dalian,Liaoning Telephone:18841186255 mailbox:dsy@plasticdl.com